Our Team

New Team Members

Natalie Shannon

Natalie Shannon (LightForm Project Manager) has recently joined LightForm as Project Manager, previously the Project Manager for The University of Manchester - Study China programme, a UK government funded programme and the largest China outbound mobility programme delivered in the UK. Natalie has considerable experience in project, operations management and strategic planning, with expertise in the execution of multiple, target-driven contracts, including programmes for Department of Education and Training and Development Agency.

Dr Pratheek Shanthraj – Airbus Research Fellow

Pratheek has 10 years’ experience in computational mechanics, microstructure physics and scientific software development at leading institutes in the US, Germany and Japan, he has joined us from the Max-Planck-Institut für Eisenforschung, to take up the Airbus Research Fellowship at Manchester. Pratheek obtained his PhD in Electro-Thermo-Mechanical Modeling at North Carolina State University and is an expert in coupled phase field-crystal plasticity modelling and is the leading developer of the DAMASK (https://damask.mpie.de). He will work on modelling the combined influence of deformation, and phase transformations and in two-phase titanium forging.

Dr Jinghua Zheng

completed a PhD in Mechanical Engineering at Imperial College London, during which she developed a constrained ageing technique for residual stress reduction in aluminium aircraft components. She also established and validated physically-based constitutive equations and for FE models of residual stress and yield strength distributions in components. Based at Imperial College London, Jinghua’s work in LightForm focuses on optimizing and modelling the age hardening response in the HFQ process. This includes an examination of the age hardening properties and considering the effects of prior dislocations. Jinghua will also develop a phenomena-based model to capture the basic ageing mechanisms (i.e. nucleation, growth, coarsening, dissolution of the precipitates) and the interactive relations between ageing and dislocation evolution. Crucially this model is expected to be implemented into FE simulations of the HFQ process modelling.

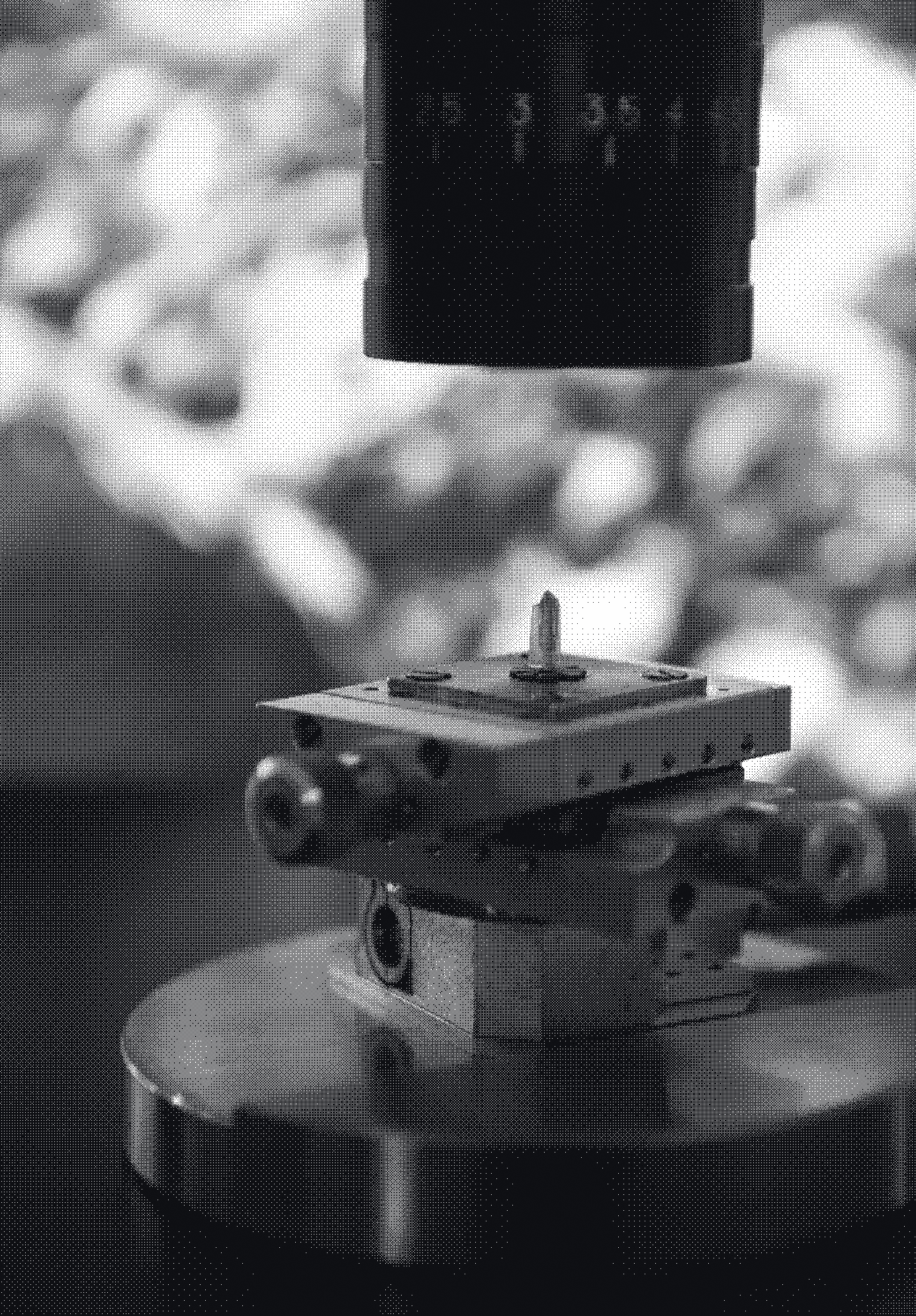

Dr Christopher Stuart Daniel

Dr Christopher Stuart Daniel recently obtained his EngD from the University of Manchester with a thesis on the development of crystallographic orientations (textures) during hot-rolling of dual-phase zirconium alloys. In LightForm, Christopher leads the in-situ characterisation of light alloys and is working to develop in-situ characterisation capabilities for studying the micro-mechanics of deformation at elevated and hot and warm forming temperatures in Ti, Al and Mg alloys, including the development and building of bespoke rigs for use with synchrotron diffraction, neutron diffraction and electron microscopy. Christopher’s work is intended to broaden knowledge of the dynamic mechanisms, active during forming, that contribute to the microstructural evolution and precipitate formation during forming of advanced light alloys.

Dr Patryk Jedrasiak

Dr Patryk Jedrasiak completed an MPhil in Engineering and a PhD in numerical modelling of friction welding at the University of Cambridge, where he is now a Research Associate. Patryk’s research experience includes a fellowship at Harvard University, focusing on a novel Eulerian numerical method for simulating elastoplastic solids, 3 years part-time at the industrial sponsor of his PhD, The Welding Institute, as well as undergraduate research placements at Imperial College London and fka Aachen (part of RWTH Aachen). Patryk has also completed internships with Centro Ricerche Fiat, McKinsey & Co., and NATO, working on major engineering challenges: electric vehicles, energy strategy and autonomous systems. Patryk’s work with Lighform focuses on microstructure-informed, computationally efficient thermomechanical finite element modelling of innovative forming processes, for light alloys.

Dr Paloma Hidalgo-Manrique

Dr Paloma Hidalgo-Manrique completed a PhD at the Complutense University of Madrid, focusing on the processing of fine-grained microstructures by accumulative roll bonding, and how it can be used to produce material that can be superplastically formed more easily. Since then she has worked on the fundamental deformation mechanisms in Mg alloys as part of LATEST2 and project MAGMAN. Paloma’s work in LightForm will extend and optimise the Hot Form Quench (HQF) process in Al alloys, involving a systematic analysis of the effect of different processing parameters on the resulting microstructures and performing detailed characterization of the latter, by a combination of complementary techniques including scanning and transmission electron microscopy.

Dr Adam Plowman

Plowman has recently completed a PhD at The University of Manchester, using first principles atomistic simulation to study zirconium grain boundaries, with the aim of understanding the pellet-cladding interaction in the fuel rod cladding tubes of light water nuclear reactors. In LightForm, Adam will create a framework to improve modelling capabilities in assessing the formability of light alloys. This will include exploring crystal plasticity methods and phase field modelling and applying them to predict microstructure development during warm forming and forging.

Dr Alex Cassell

Cassell has worked on several research programmes since completion of a PhD on the environmentally assisted degradation mechanisms in light alloys. Working in the Corrosion and Protection Centre he has expertise on the multi-scale characterisation of high performance aluminium alloys. His research has included the study of hydrogen embrittlement (HE) and stress corrosion mechanisms in light alloys, the development of new corrosion protection systems for high performance aerospace aluminium alloys, as well as research on forming techniques for integration of light weight alloy systems into land transport vehicles. Alex’s work in LightForm aims to improve our understanding of the degradation mechanisms in high performance light alloys formed using existing and new processes, and their behaviour in demanding environments.

Dr Nicolas Gruel

Dr Nicolas Gruel completed a PhD in astrophysics and a Post-Doc in software development for data acquisition, analysis and simulation of astronomical images. As the lead developer for the Centro de Estudios de Física del Cosmos de Aragón, Nicolas was accountable for creating the data pipeline to analyse 1.4 TB of data per day, moving then to the University of Sheffield where he led the Insigneo Institute Computer Science engineering team. As a Research Software Engineer at The University of Manchester, Nicholas’s work involves collaborating with researchers in various fields, such as Humanities, Computer Science and Materials Engineering, supporting their research by managing their software development and/or optimization as well as data management. Nicolas’s work in LightForm will be to create a multiplatform data infrastructure to which LightForm data can be uploaded, shared and managed.

University of Manchester

-

Prof Phil Prangnell (Director)

-

Prof Joe Robson

-

Dr João Quinta da Fonseca

-

Prof Xiaorong Zhou

-

Dr Michele Curioni

-

Dr Sarah Haigh

-

Dr Chris Race

-

Dr Pratheek Shanthraj