News, Views & Events

News

Developing nanoscale EBSD mapping technique and methodology to quantify Ti-6Al-4V texture data in large samples

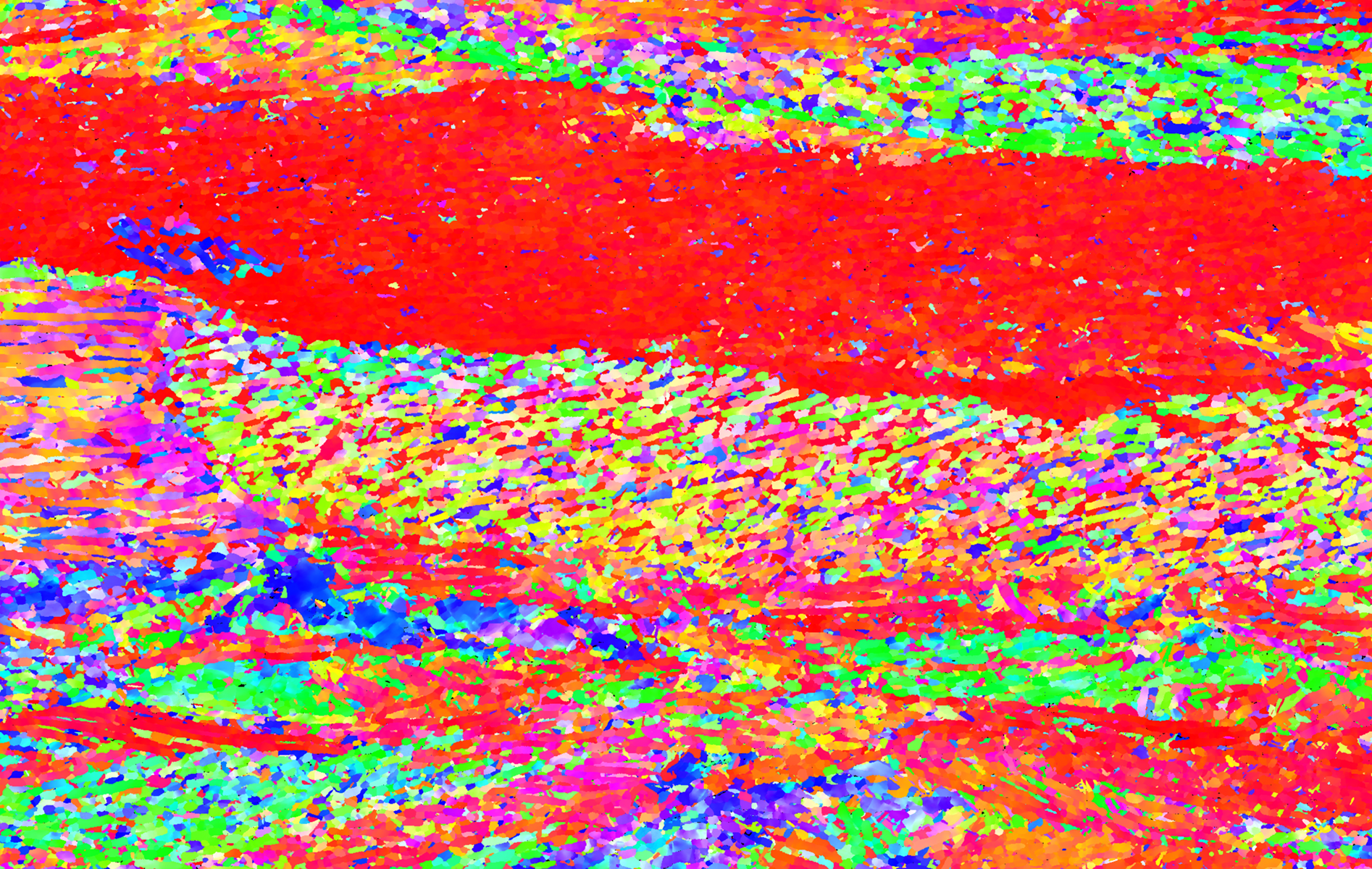

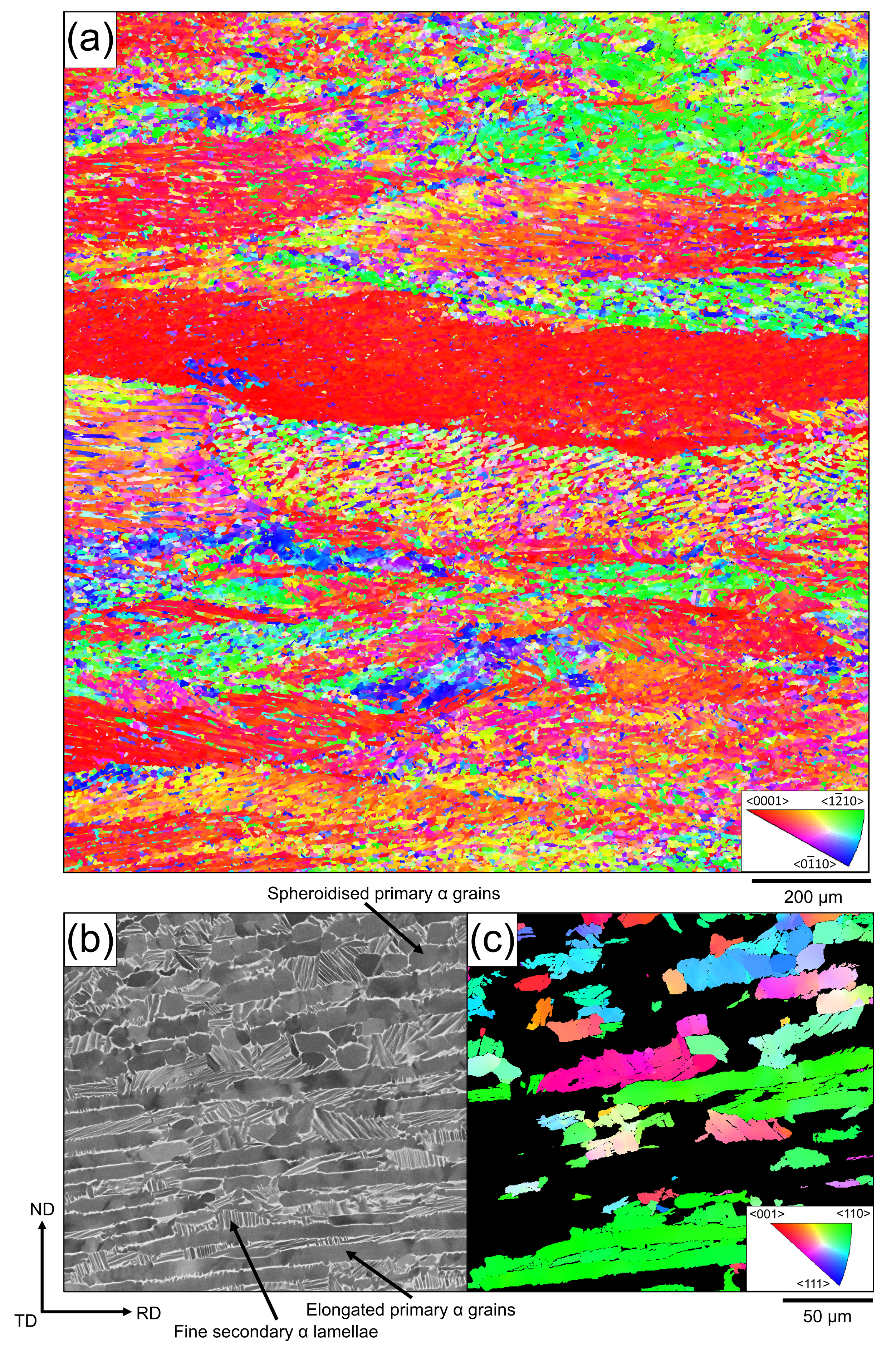

Wrought Ti-6Al-4V (Ti64) products can suffer from heterogeneous textures that lead to mechanical anisotropy and uncertain damage tolerance in key aerospace applications. Therefore, it is important to understand how these textures develop during thermodynamic processes such as rolling and forging. Crystallographic textures are commonly investigated using X-ray diffraction; however, this technique gives no spatial information, only orientation data, so characterising the texture bands that are heterogeneously spaced throughout Ti64 billet and plate thicknesses cannot utilise this method. Electron backscatter diffraction (EBSD) mapping in the scanning electron microscope (SEM) is used instead, as this provides all the necessary information. Unfortunately, due to the β → α phase transformation in Ti64, which occurs during cooling after thermomechanical processing, we can only inspect post-mortem microstructures that are dominated by the α phase (>80% volume fraction). EBSD reconstruction techniques are available that utilise the orientation relationship between the two phases to restore the β microstructure as it was before material cooling, but the deformation during processing destroys a significant fraction of this orientation relationship throughout the microstructure. So, we must instead rely on mapping the residual β phase in the room-temperature microstructure to obtain the texture data instead.

The residual β phase is of the scale of hundreds of nanometres, and due to the scattering of the SEM electron beam throughout the material, which interacts with more α phase than β, the β diffraction signal is lost and texture data cannot be collected conventionally. In this work, we optimised the SEM and EBSD experimental parameters to maximise indexing of the residual β phase, integrated these settings into a large-area-mapping format, and demonstrated the ability to increase the mapped area fraction with EBSD from <1% to ~6%. Through this methodology, texture data – orientation and spatial data – from large Ti64 samples can now be captured reliably and efficiently.