News, Views & Events

News

Understanding Cold Creep and Fatigue Crack Initiation in Ti Alloys

LightForm researchers have recently published new results that shed new light on the elusive mechanisms responsible for cold creep and fatigue initiation in Ti alloys. Titanium alloys have unique properties that make them the material of choice in applications like aeroengines and frames. They have unbeatable strength for their weight, and good compatibility with other advanced materials like carbon fibre reinforced composites.

Like all metallic materials, titanium alloys are prone to failure by fatigue, and in alloys like Ti6Al4V, this can be exacerbated by long dwell periods at load, during which creep occurs even at room temperature. This dwell debit on fatigue is driven by local plasticity at the microstrutural level, which is in turn affected by the microstructure of the alloy.

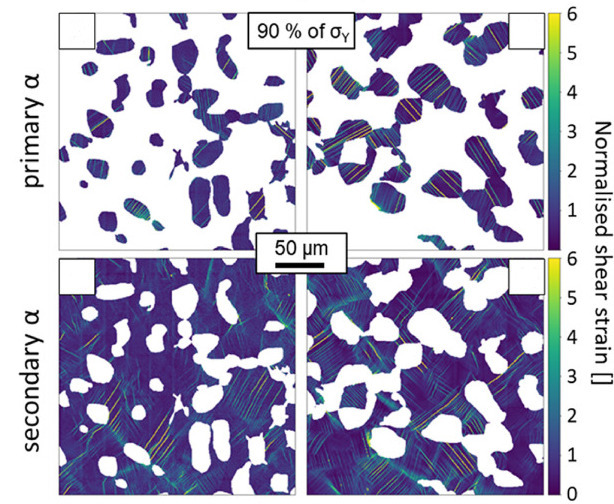

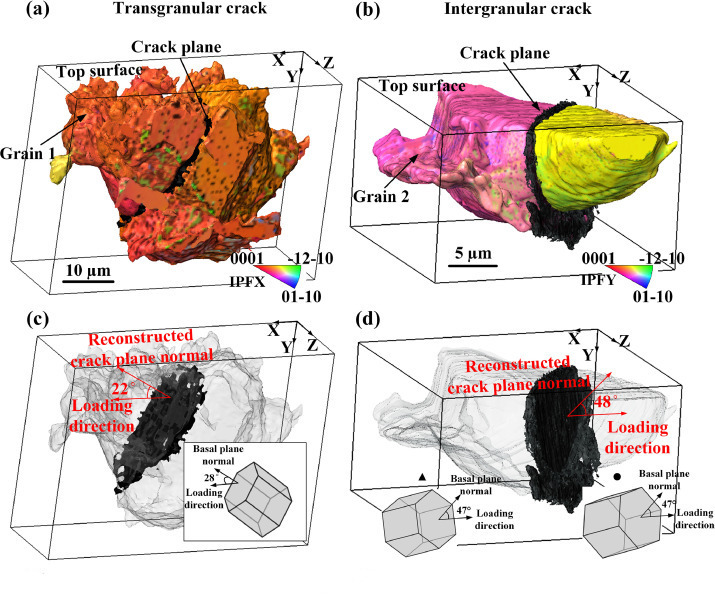

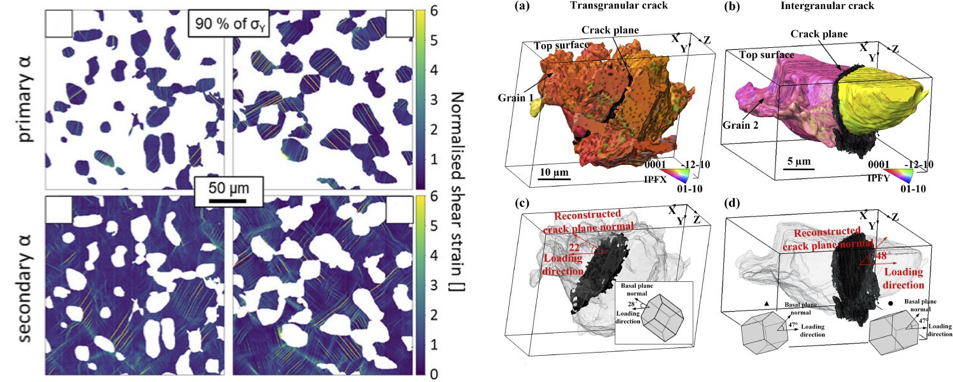

In two new studies in collaboration with Rolls-Royce Plc, we have used a new technique developed at Manchester called High Resolution Digital Image Correlation, to measure local plasticity at the scale of the microstructure when the material is loaded to very low stresses. In a creep study by Manchester PhD student Claudius Dichtl (see article here), we found that early plasticity is dominated by basal slip which concentrates on the primary alpha grains of the material. Computational modelling was also used to explain how this behaviour could be affected by residual stresses and the inherent elastic anisotropy of Ti. In a parallel study, Manchester PhD student Conghui Liu (see article here) discovered that during fatigue loading this local deformation on basal planes can lead to early crack initiation, especially when the plasticity produces slip steps at the surface, and also when it occurs at special twist grain boundaries.

These new results not only help us understand how the microstructure of the alloys currently used in aircraft and engine manufacture can be optimised, but also helps guide the development of future, more fatigue resistant alloys.