Research Projects

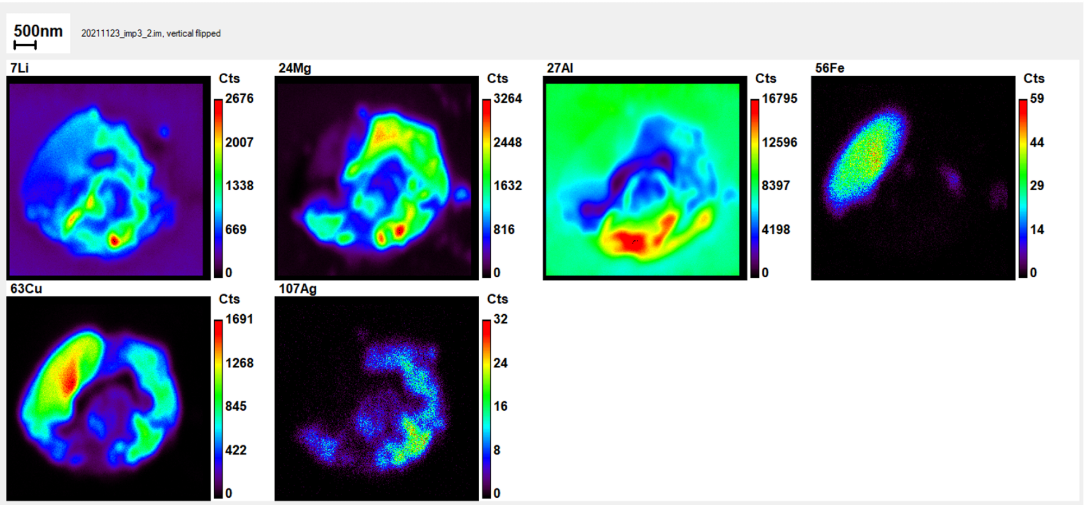

Characterisation of Aluminium-Lithium Alloys Using NanoSIMs

Due to the improved properties the addition of Li has on the Al alloy system, Al-Li alloys have now become one of the most widely used groups of aluminium alloy classes and have been extensively used for aerospace industry. This is because density is such an important factor in aerospace applications along with the increasing demand for low fuel consumption to help protect the environment and save cost. For every 1% of Li added to the aluminium alloy, the alloy density is reduced by 3%. Al-Li alloys have emerged as powerful material option for both military and civil flights. Al-Li has been an object of research since the 1920s, with three generations of Al-Li alloy systems developed so far. The distributions of Li and its precipitates have a major effect on the properties of the alloy. However, the main problem faced in the development of Al-Li alloys, due to the fact that Li is such a light element, is that it is very difficult to spatially localise the Li distribution. Only a few characterisation techniques can achieve the this. In this project, the capabilities of high spatial resolution secondary ion mass spectrometry (NanoSIMS 50L) along with Electron Probe Microanalysis (EPMA) to characterise Wire + Arc additive manufacturing (WAAM) produced 2xxx Al-Li alloys will be investigated.