Research Projects

Titanium and Magnesium

A novel and cost effective method to manufacture magnesium alloy sheets

Magnesium is the lightest structural metal, its density is about 2/3 that of aluminium, and 1/4 that of steel. It should have great potential in the automotive industry. However, the applications of magnesium alloys are always limited, especially using magnesium alloy sheet. The reasons for their limited use are: (1) the high cost of magnesium sheet; (2) the poor ductility of magnesium at room temperature. In order to reduce the cost of Mg alloy sheets and improve the efficiency of manufacturing Mg alloy sheets, a novel and cost-effective method to manufacture Mg alloy sheets will be developed.

Compression and tension tests will be performed, simulating the rolling process, to find the optimal forming window. Rolling tests will be conducted to verify the feasibility of the novel and cost-effective methods to manufacture Mg alloy sheets. Microstructure examination (e.g. SEM, EBSD, etc.) will be performed to study the mechanisms in these methods.

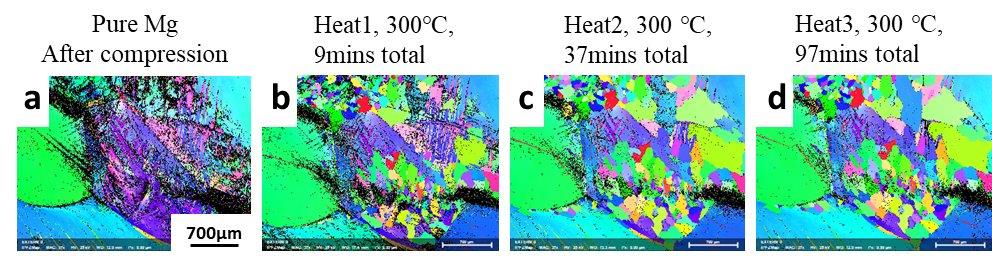

Latest results (Microstructure evolution of pure Mg in static recrystallization):

1. Quasi-in-situ EBSD for microstructure evolution of pure Mg in static recrystallization

Compression tests was done for pure Mg to achieve pre-deformation;

Study the microstructure evolution of pure Mg in static recrystallization to understand the mechanisms of recrystallization in hot rolling process.