Research

Titanium and Magnesium

Titanium Ti-6Al-4V alloys are ubiquitous in structural aerospace components due to a high specific strength and fatigue...

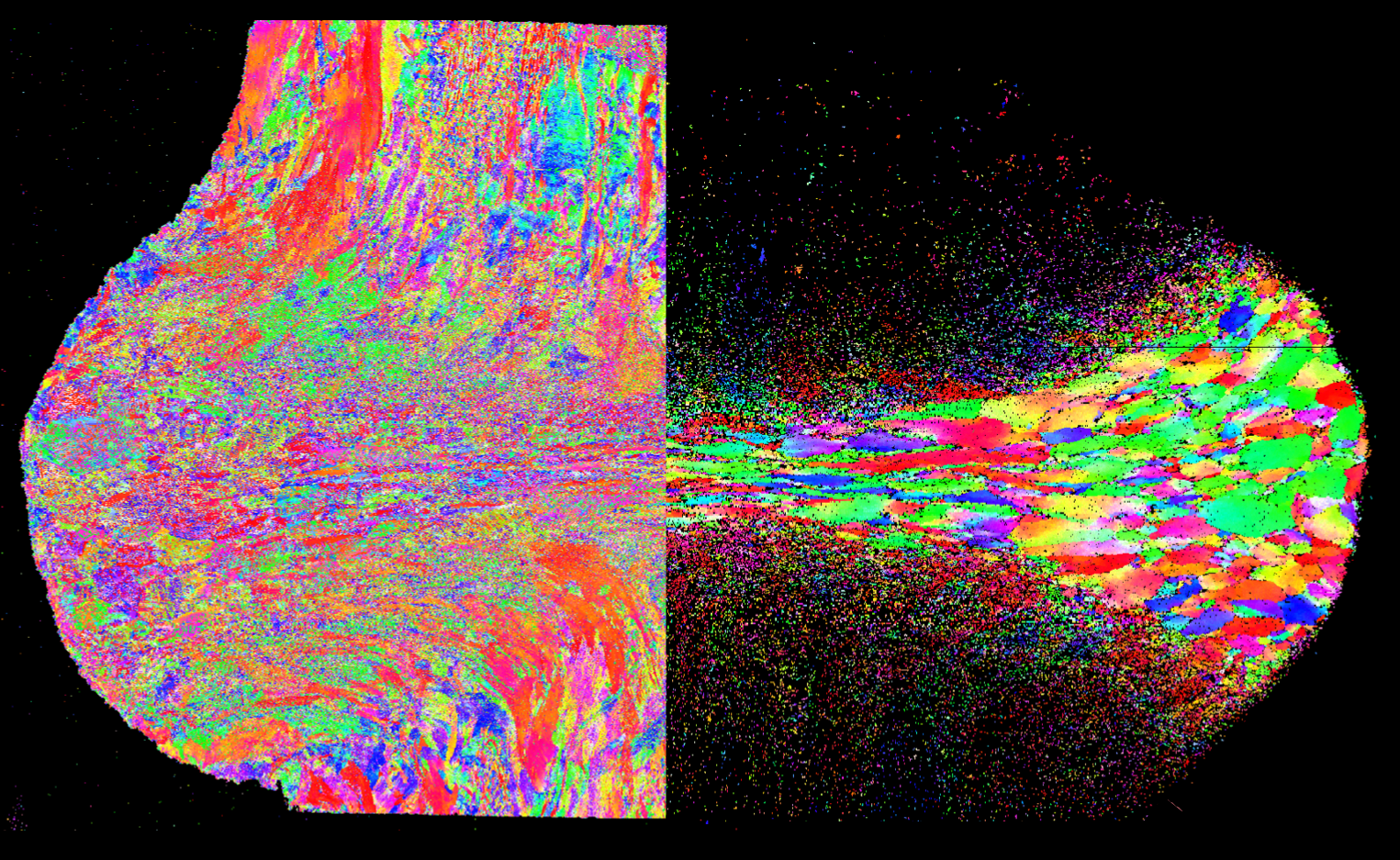

Magnesium is the lightest structural metal, its density is about 2/3 that of aluminium, and 1/4 that of steel. It should...

Failure initiation during monotonic and cyclic loading of polycrystalline metallic materials alloys involves irreversible deformation with increasing applied stress,...

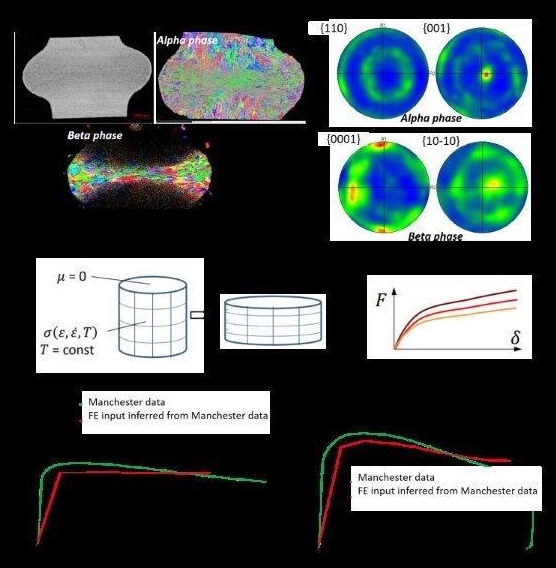

When forging large billets of titanium, microtextured regions can form. After doing a heat treatment above the beta tranus,...

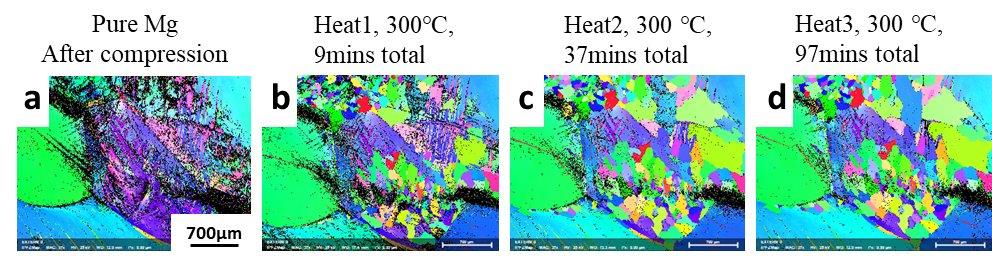

The aim of the work is to investigate microstructural evolution of dual-phase titanium (e.g. Ti64) under hot rolling....

This project is in partnership with Rolls-Royce at the University of Manchester, University of Sheffield and University College Dublin....

Direct energy deposition additive manufacturing processes, such as wire-arc additive manufacturing (WAAM), offer the high kg per hour deposition...

To meet the demand for lower global emission and fuel consumption, the application of titanium alloys with high strength...

The aim of this project is to study the development of the microstructure in Ti alloys during thermo-mechanical processing....

Magnesium alloys are the lightest metal structural materials, with high specific stiffness and specific strength, and therefore it is...

Magnesium alloys, as the lightest structural metallic materials that human being has ever discovered, could revolutionize modern...

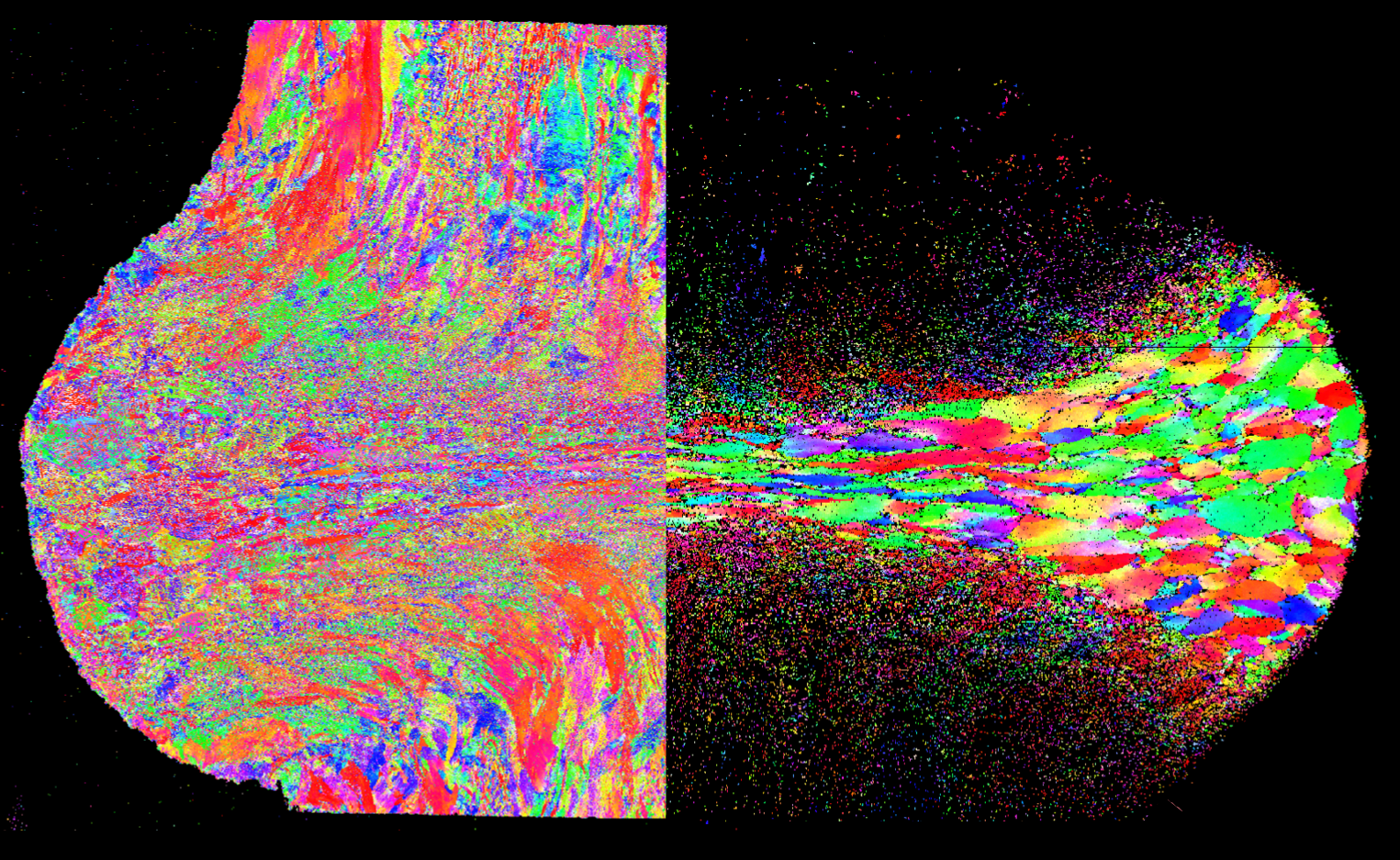

Microstructure and crystallographic orientation (texture) in dual-phase Ti-6Al-4V materials is controlled by thermomechanical processing during manufacture, offering...

Dual phase Zr-2.5Nb alloys have superior strength and fracture toughness compared to single phase Zr alloys. Optimising the...

Titanium 64 is widely used in the aerospace industry despite the high costs associated with production. In order to produce...

Cold dwell causes creep deformation to occur at room temperature, lowering the overall fatigue life of the compressor disk....

Thermo-mechanical testing is routinely used for replicating the exact thermal and mechanical processes that a material is subjected to...

Thermo-mechanical processing, such as hot-rolling or forging, are established processes to improve mechanical properties and to homogenize the microstructure...

The warm deformation performs below the recrystallization temperature which leads less additional softening due to recrystallization. The texture changes...

The microstructures of novel rare earth containing magnesium alloys are being controlled through heat treatments and characterised using SEM...

This project aims to investigate the texture evolution mechanism of Ti-6Al-4V during hot rolling. The materials provided...

Titanium alloys are used in a wide variety of components throughout the fan and compressor stages of an aero-engine....

High performance titanium alloys are being increasingly used in advanced airframes, particularly where elevated temperatures are experienced (e.g....