Research Projects

Titanium and Magnesium

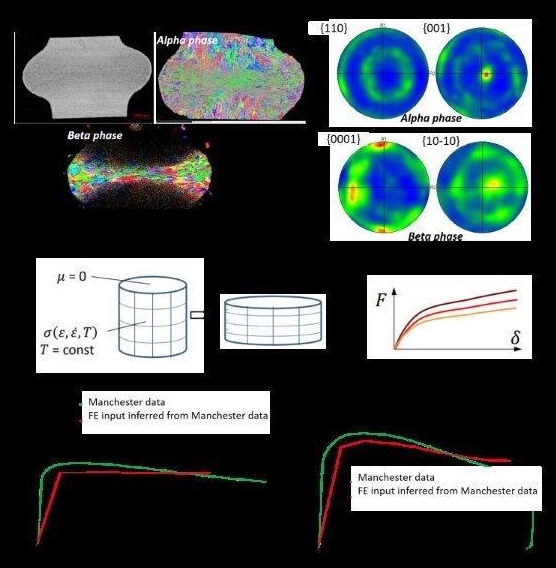

Lab scale simulation for thermo-mechanical processing of dual-phase Ti alloys

Thermo-mechanical testing is routinely used for replicating the exact thermal and mechanical processes that a material is subjected to during the manufacturing process. Laboratory testing equipment have typically high-speed heating systems and servo-hydraulic systems that can be used as a fast simulation tool, to analyse the effect of various parameters such as temperature and strain rate on deformation behaviour and microstructure development. Fast thermo-mechanical testing is particularly advantageous for optimizing processing routes, by reducing product development and processing costs. However, dual-phase Ti alloys have a strong tendency to exhibit flow localization in the high temperature α + β regime, exhibiting significant barrelling during hot compression testing at the lab scale, which casts doubt over the accuracy of the flow curves. There are several extrinsic and intrinsic factors which can be considered responsible for barrelling, such as temperature gradient across the sample, friction between sample and platens, specimen size effect and the complex interaction between α (hexagonal-close-packed, hcp) and β (body-centred-cubic, bcc) phases.

In this project, we aim to delineate the contribution of the individual factors and understand to what extent each factor affects the flow behaviour. We also aim to develop testing procedures to ensure best practices when using present state of the art equipment’s such as Gleeble, Dilatometer and Servotester, ensuring accurate simulations of Ti industrial forging procedures. Apart from conducting systematic experiments, the project also involves finite element modelling of the hot compression tests in collaboration with the University of Cambridge.

To date, hot compression tests of Ti-64 and Ti-407 samples were performed at three different temperatures and strain rates using a dilatometer (DIL805A/D/T. Quenching, Deformation, and Tension Dilatometer). The three temperatures correspond to three different phase regimes – dominant α, dominant β and α + β. It was observed that barrelling is only prominent in theα + β regime, which highlights the importance of understanding a dynamic interaction between α and β phases during deformation. Experimental setup on the dilatometer was also optimised by minimising temperature differences across the length of the compression sample, by using molybdenum discs and alumina platens.