Research Projects

Titanium and Magnesium

Developing a coupled crystal-plasticity phase-field model to understand microstructural evolution during hot rolling of dual-phase titanium

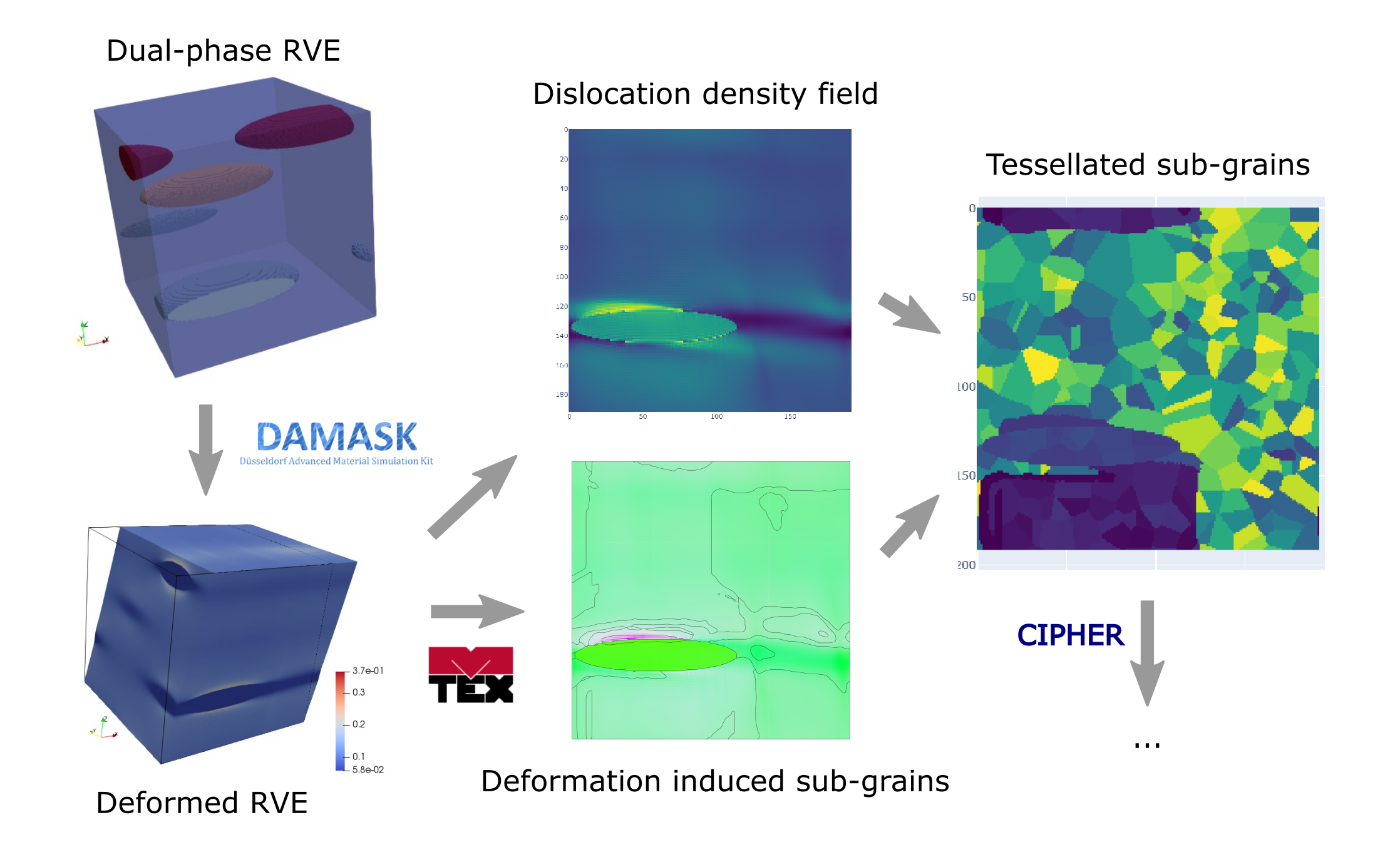

The aim of the work is to investigate microstructural evolution of dual-phase titanium (e.g. Ti64) under hot rolling. Ultimately, we aim to develop a coupled crystal plasticity (CP) and phase field (PF) model that can track the kinetics of microstructural development during hot rolling. We will use insight from the model to understand experimental observations, and to provide guidance on the mechanisms at play during hot rolling of these alloys.

The coupled model will be developed as part of the DAMASK crystal plasticity package. However, since this approach will require substantial time for code development and testing, we will, initially, also investigate “static” microstructural transformation. In this case, we will firstly perform CP simulations of a suitable dual-phase representative volume element (RVE). We will then use various methods to identify a region of interest on the deformed RVE, which can then be fed into a phase field-model in order to investigate the kinetics of the microstructure development. For example, we will run a grain-growth model on the region of interest.

Progress so far:

- We constructed a representative volume element (RVE) of dual-phase titanium composed of a small alpha-phase colony within a beta-phase matrix. The starting orientations of the alpha-phase particles and the beta phase matrix were specified to satisfy the Burgers orientation relationship and the observed habit plane of the alpha-phase particles.

- We simulated using DAMASK simple shear in both “soft” and “hard” loading directions, with respect to the alpha-phase particles.

- We performed fast multiscale clustering (using MTEX) on a 2D slice of the final orientation field in order to identify deformation induced sub-grains.

- We then estimated the dislocation density field and distributed seed points within each sub-grain in proportion to the dislocation density. We then performed a Voronoi tessellation of these seed points within each sub-grain. This aims to mimic the recovery process.

- Our next steps include using this new microstructure map within a grain-growth phase field simulation using the CIPHER package