Research Projects

Titanium and Magnesium

High Performance Wrought Magnesium Alloys

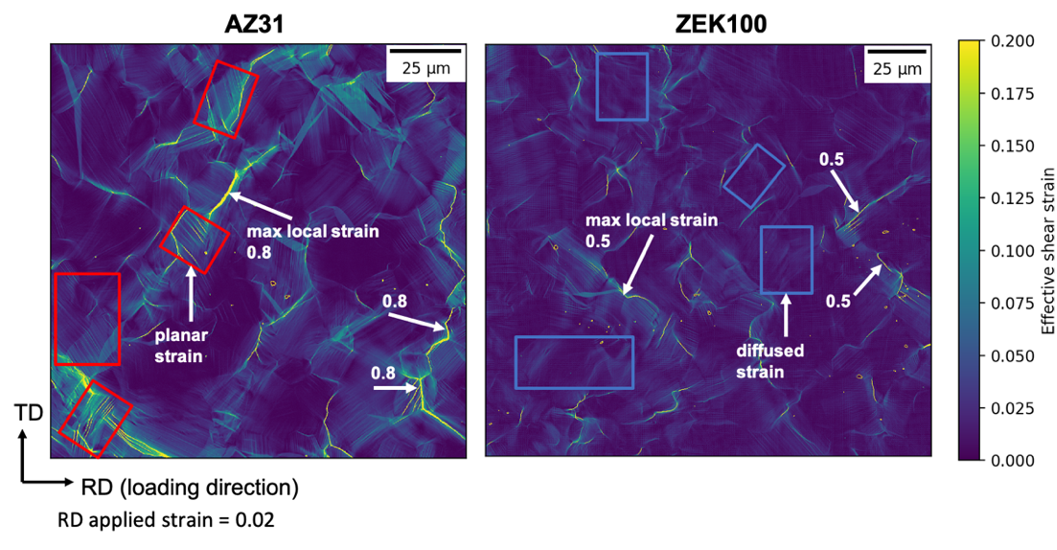

Magnesium alloys, as the lightest structural metallic materials that human being has ever discovered, could revolutionize modern industries. However, the formability of magnesium alloys is very weak at room temperature due to the HCP structure. For wrought products, the deformation could be heterogeneous with a combination of slip and twining which provide large local variation in strain. This PhD project will use the High-Resolution Digital Image Correlation (HR-DIC) technique to study the strain distribution in both AZ31 and ZEK100 wrought magnesium alloy sheets during the complex deformation process like uniaxial and biaxial stretching and to understand the vital differences between these two materials deformed at micro-structural scale. It will also help us understand role of microstructure and texture in controlling strain localization and distribution during forming process by using complementary techniques such as high-resolution SEM and EBSD in each material. Outcomes of this research will be used to infer a failure criterion and finally predict the formability of magnesium sheets by linking to CPFEM crystal plasticity model.

Our recent results showed the strain distribution in rolled AZ31 Mg sheet is very heterogeneous after uniaxial elongation along RD - most intragranular strains have sharp planar feature. Strain localizations found at grain boundaries of AZ31 can be upgraded to 80% which is almost 40 times larger than the 2% applied strain. The other rolled Mg sheet ZEK100, with a weaker and different texture, exhibits a more uniform distribution of strain and less strain localization at the grain level after the same tensile test - the majority of strains in ZEK100 have diffused features where the strain intensity is close or even lower than the applied strain. However, strain localizations were also detected in ZEK100, those maximum strains can be 25 times higher than the 2% macro strain.