Research Projects

Aluminium

Microstructure effects on EAC behaviour of 7000 series Al-alloys in humid air

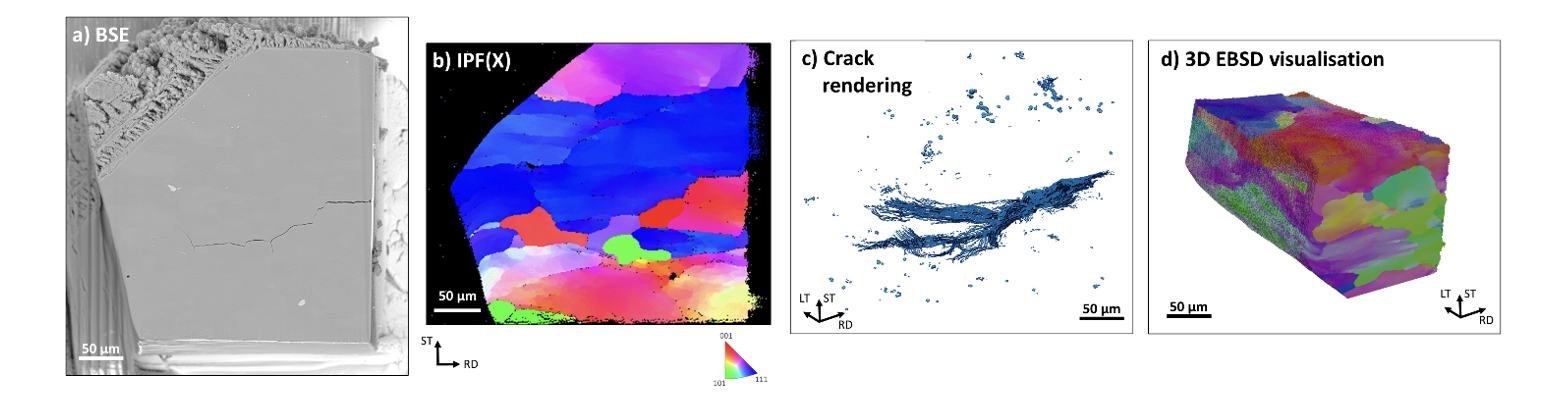

The higher susceptibility of new-generation 7xxx series aluminium alloys, such as AA7085, to environmentally assisted cracking (EAC) in humid air, compared to established alloys such as AA7050, has been demonstrated recently. At present, however, the factors leading to their inferior performance require better understanding. This project aims to investigate the influence of microstructure on EAC in 7xxx series alloys. This will include 4-point bend testing AA7085 and AA7050 specimens with different grain structures, tempers, etc, in humid air until failure. Post-mortem characterisation will include high-resolution SEM fractography, EDS, and STEM of the EAC initiation sites, which are non-ambiguously detected from optical microscopy data acquired in-situ during the failure tests. 3D imaging of select initiation sites, via Laser-PFIB serial sectioning will be undertaken, to better understand the microstructural features which define preferred EAC initiation sites. An example of a recent LPFIB dataset for a EAC initiation site in AA7085 is presented in Figure 1, below.