Research

Aluminium

In the defence sector, the high strength to weight ratio of light alloys can be utilised in numerous ways...

The 7xxx series of aluminium alloys have exceptionally high strength and are used for structural applications, however some of...

7xxx aluminium alloys are the most widely used materials in the aircraft structural application due to their high strength,...

A predictive knowledge of yielding behaviour is critical to improve our understanding of the mechanical anisotropy of light alloys...

Background: Creep-age forming (CAF) is a forming technique used for fabricating large/extra-large lightweight aircraft panel components....

When bending is applied to Al sheets, early failure may appear between grain boundaries on the surface deformed in...

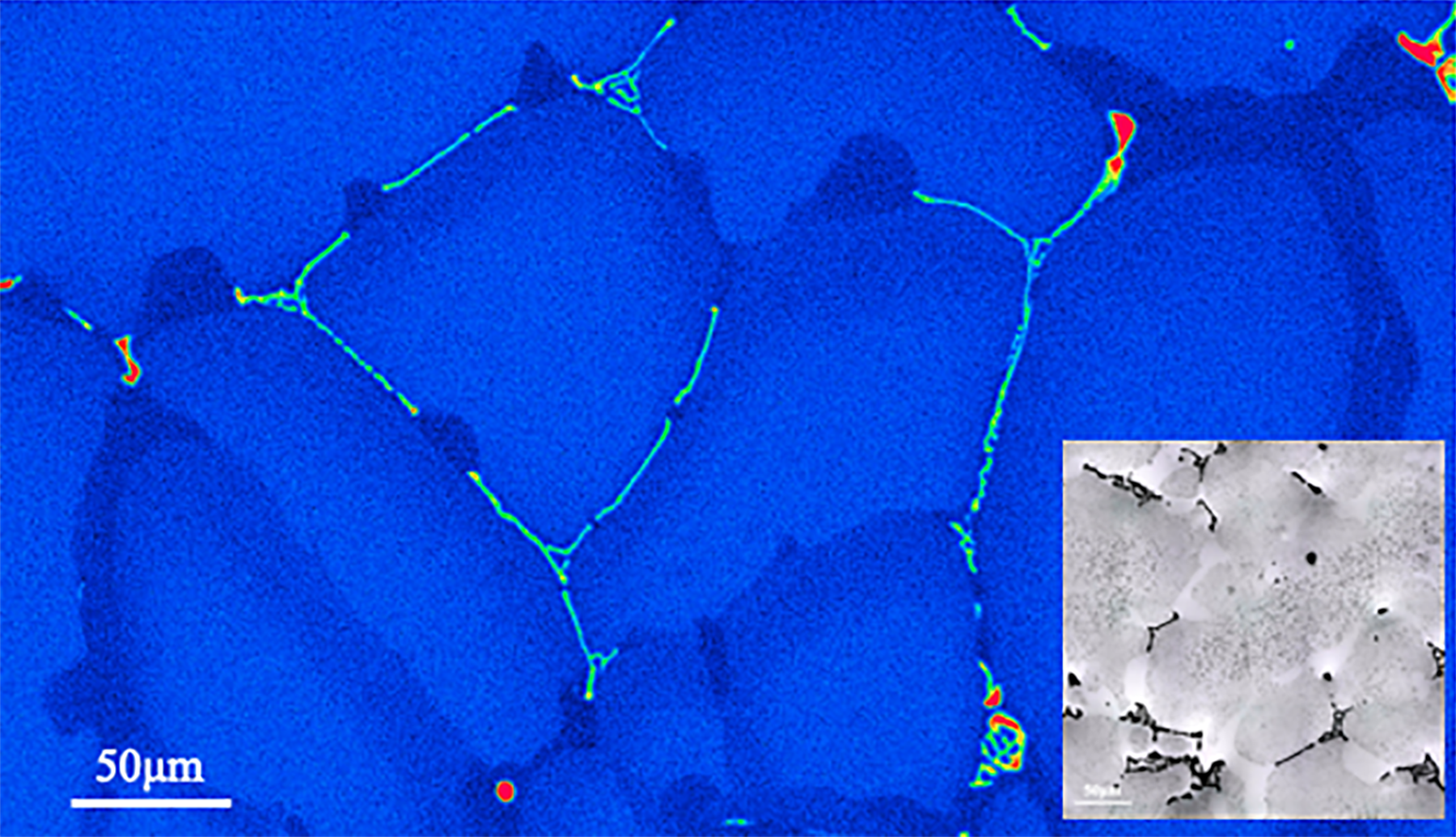

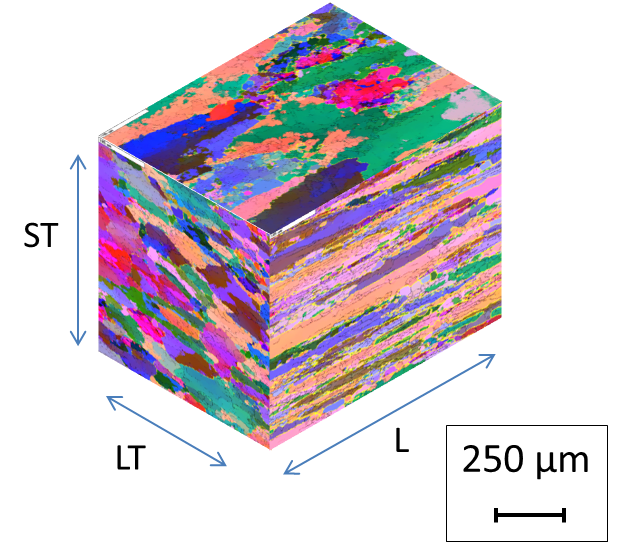

This project involves using crystal plasticity modelling to explore the effect of primary particle size distribution, volume fraction and...

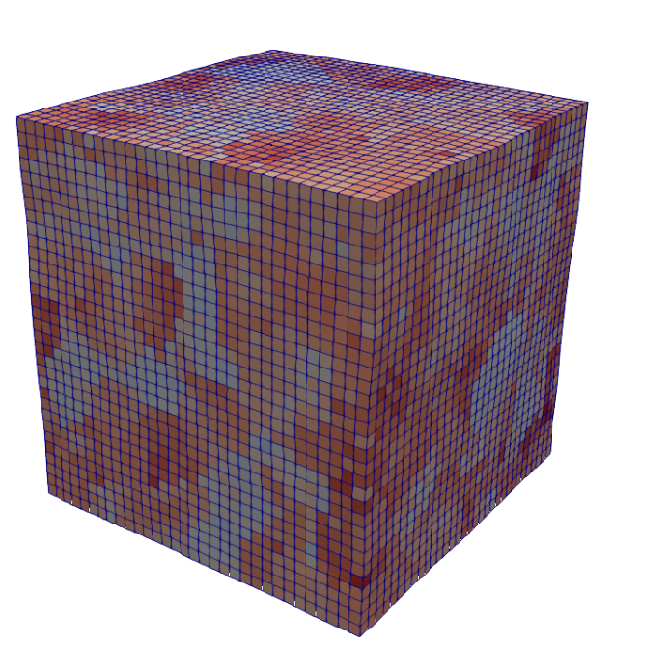

Background: Solution heat treatment, Forming and cold die Quenching (HFQ®) is a technique that enables mass production of...

This project focuses on developing innovative methodologies to perform laboratory corrosion testing of surface treated light alloys. In particular,...

7075 aluminium alloy is widely used in automobile manufacturing, aerospace, and other fields like military, due to its high...

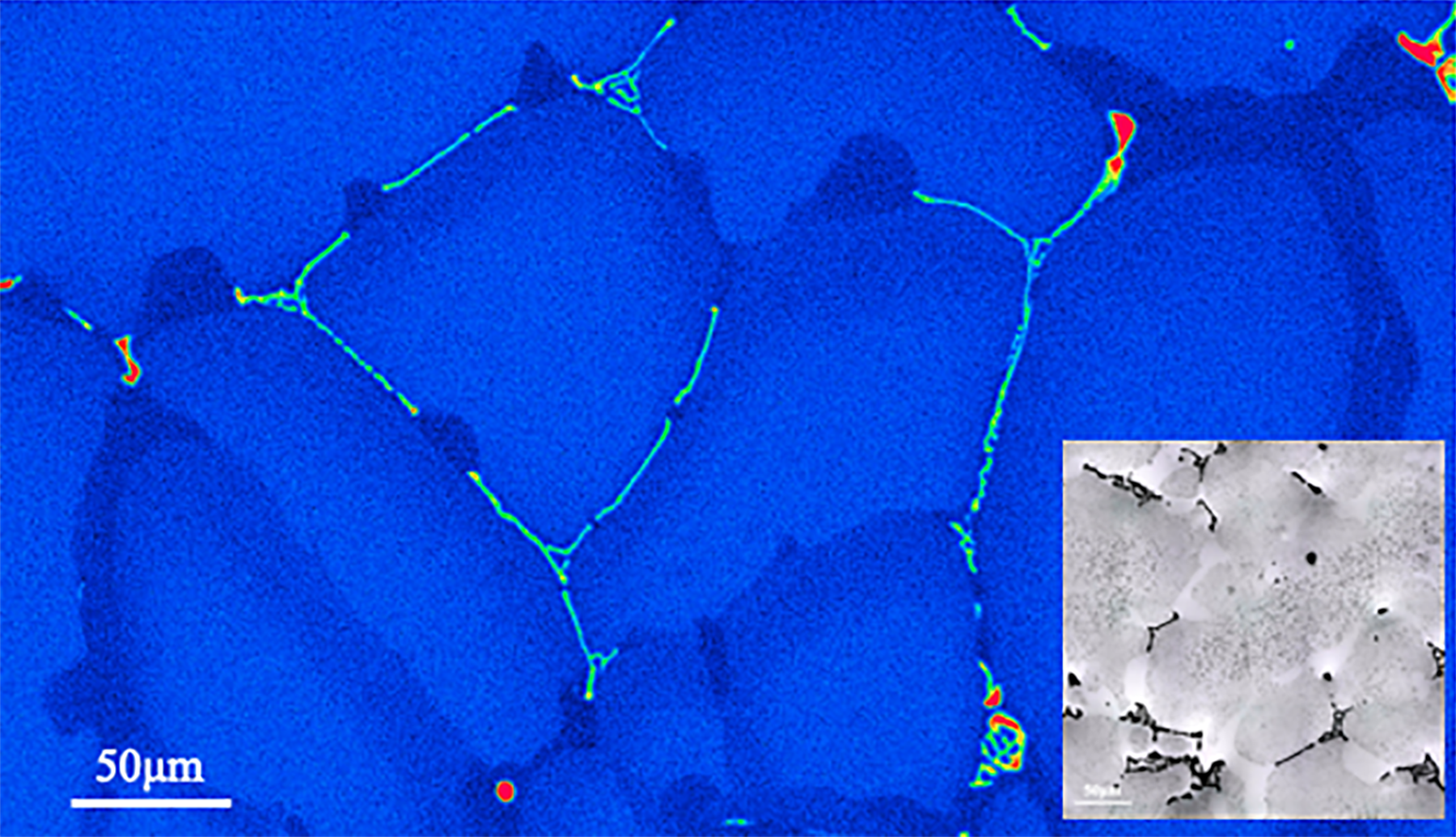

7xxx series aluminium alloys have important applications in the aerospace industry. Understanding Environmentally Assisted Cracking (EAC) in these alloys...

Context: The need for high-strength aluminium alloys has been growing very rapidly for a decade due to their high...

The Forming limit diagram (FLD), which represents the limit strains for a material deformed under the different strain states...

A finite element model accounting for friction, barrelling, and temperature gradient has been developed. This will be used to...

Hot Form Quench (HFQ) is a process in which stamping and heat treating are combined in a single operation...

The aim of this project is to refine existing crack growth models to be more realistic of...

Titanium 64 is widely used in the aerospace industry despite the high costs associated with production. In order to produce...

The objective of this project is to investigate the effect of alloy composition and metallurgical state...

In this project the effects of intermetallic compound particles on the formability and mechanical properties of the...

Using secondary/recycled aluminium alloys offers significant advantages due to the lower cost and much less energy consumption. However,...

The higher susceptibility of new-generation 7xxx series aluminium alloys, such as AA7085, to environmentally assisted cracking (EAC) in humid...

Creep-Age Forming (CAF) as a process has demonstrated significant cost-savings in the aerospace industry in the manufacture of large-scale...

This project is focussed on the modelling the formability of light alloys during warm forming processes, so that these...

The traditional method to produce wide aluminium components is rolling, which is costly due to the multiple rolling passes...

Inspired by a recently published work of Wang et al., a novel hybrid thermo-mechanical processing route consisting of pre-ageing ...

This project aims to highlight the impact of microstructure evolution in high performance aluminium alloys produced during Hot Form...

Aluminium alloys strengthened by precipitates are widely used in the automotive and aerospace industry. Precipitation is usually achieved by...

High strength aluminium alloys such as AA7075 would make an ideal alternative to steel in the production of automotive...

There is a strong demand in the automotive industry to introduce more higher strength aluminium body panels in vehicles,...

It is difficult to predict the material properties of aluminium alloys since they are sensitive to its process history...

Despite having the key advantage of high strength to weight ratio, Al alloys lag behind in their application compared...

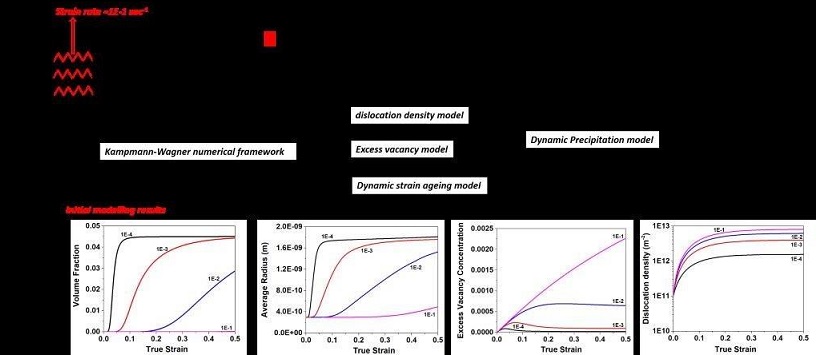

This research primarily involves studying and simulating the effect of deformation during warm or cold forming on the precipitation...