Research Projects

Aluminium

Novel Pre-age Deform and Re-age Processing Route for Tailoring Properties in Aluminium Alloys

Inspired by a recently published work of Wang et al., a novel hybrid thermo-mechanical processing route consisting of pre-ageing (PA), cold rolling (CR) and re-ageing (RA) has been investigated on AA6013 (Al-Mg-Si-Cu) system to obtain substantial strengthening while maintaining moderate ductility. The aim of this project is to find out the optimum treating parameters for AA6013, and more importantly, to develop a fundamental metallurgical understanding of the strengthening mechanisms involved in this processing route.

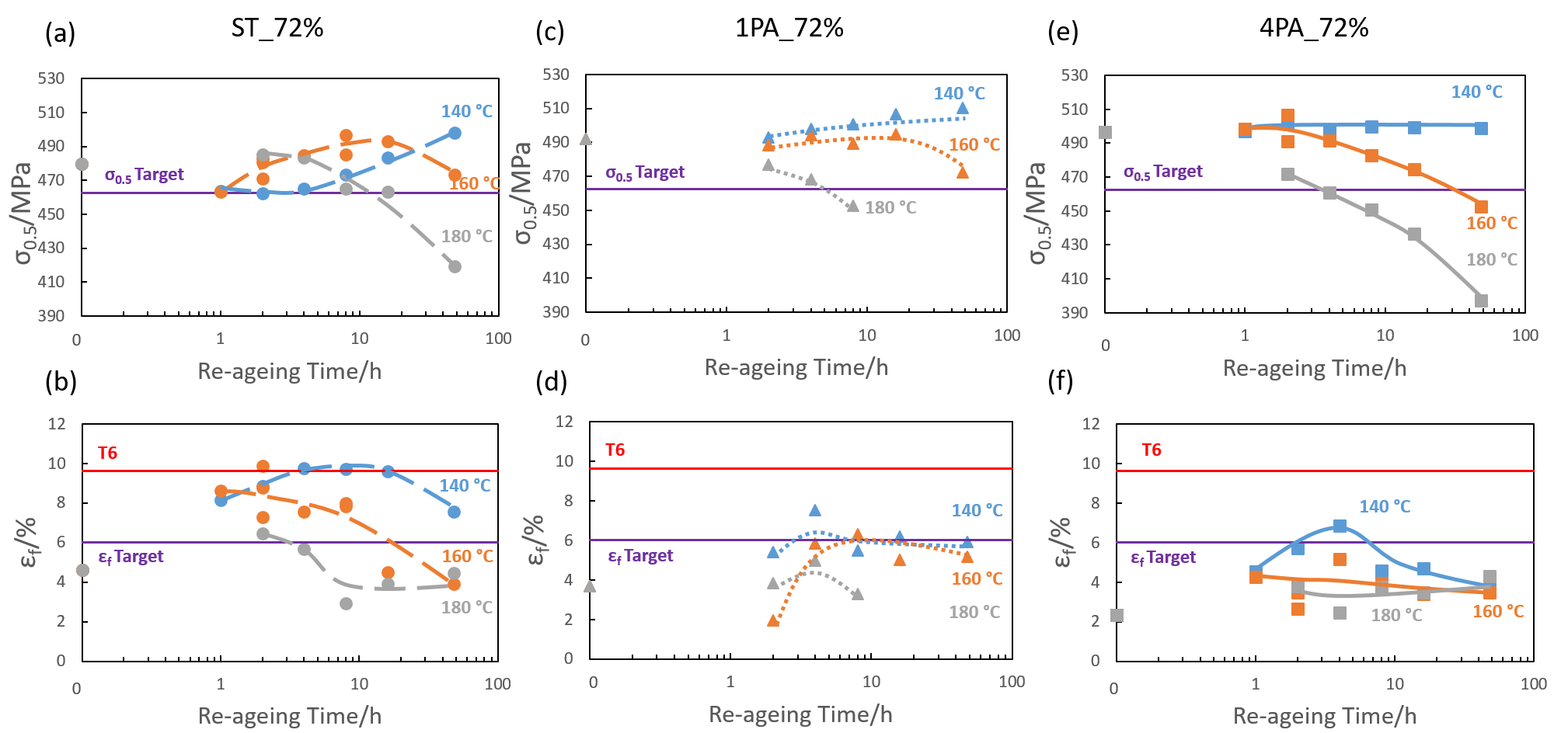

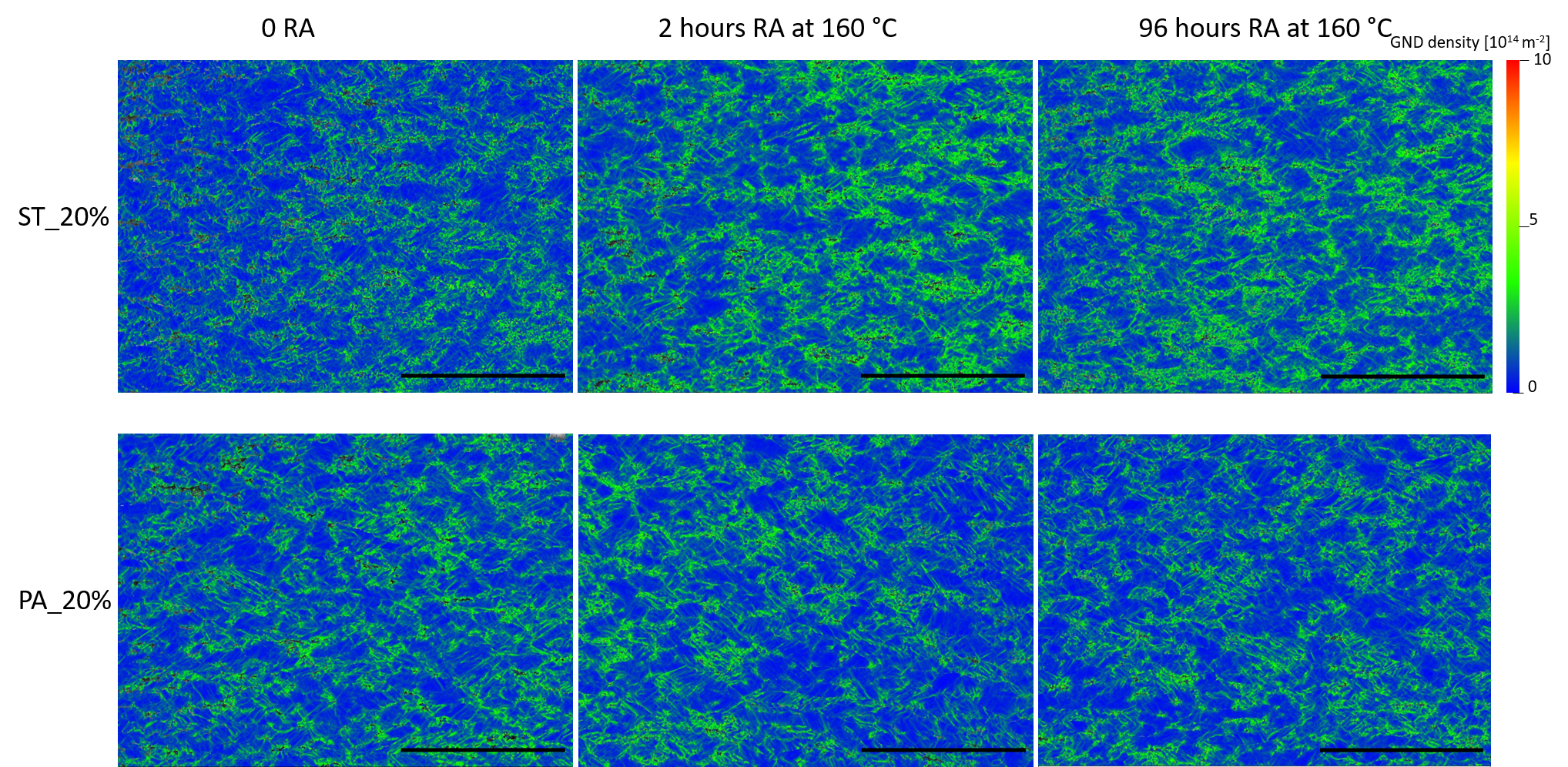

Among the samples with elongation to failure higher than 6%, the highest 0.2% proof strength was 493 MPa, reached by the AA6013 experiencing 1 hour pre-ageing at 180 °C and then 72% cold rolling reduction, followed by 16 hours re-ageing at 140 °C. However, most samples with 0.2% proof strength higher than 450 MPa and elongation to failure higher than 6% were the 72% cold rolled samples from T4 temper. During the pre-ageing step, both main strengthening precipitates in Al-Mg-Si-Cu alloy system, β” and Q’, were observed by Transmission Electron Microscopy (TEM). Compared to the samples deformed from T4 temper, the pre-aged samples exhibited higher strength at the cost of losing work hardenability and ductility. The strengthening contribution of the pre-ageing step decreases with increasing deformation strain. Higher brass component was found in the PA_CR samples due to the coherent precipitates formed during the pre-ageing. Dislocation and geometrical necessary dislocation (GND) were characterised by X-ray diffraction (XRD) and Electron Backscatter Diffraction (EBSD) correspondingly, indicating that the PA_CR sample exhibited systematically higher dislocation but with similar GND density level throughout cold rolling from 5%-20%. During the re-ageing step, only the ductility of as-rolled samples could be improved at relatively low temperature (140 °C and 160 °C) after 2-4 hours times by increasing the work hardenability with limited improvement in yield strength. The GND density in PA_CR samples, however, kept a systematically higher level than that of the as-rolled samples. For the PA_CR samples, less strengthening was observed in the re-aged samples with little improvement in ductility, which agreed with Differential Scanning Calorimetry (DSC) results. By increasing the re-ageing temperature to 180 °C, all the cold rolled samples exhibited a simultaneous decrease in both yield strength and ductility, which needed further investigation.