Research Projects

Aluminium / Data and Modelling

Towards a comprehensive understanding of dynamic interaction between dislocations and precipitates in Al-Zn-Mg-Cu alloys

Despite having the key advantage of high strength to weight ratio, Al alloys lag behind in their application compared to steel because of poor formability. Hence, several alternative strategies have been developed to circumvent the poor formability. Out of all the strategies, forming at elevated temperatures has emerged as the front runner. Hence, it is important to understand the effect of elevated temperature on the forming behaviour of Al alloys so that possible ways can be devised to improve the properties and consequently replace steel with Al alloys for structural components.

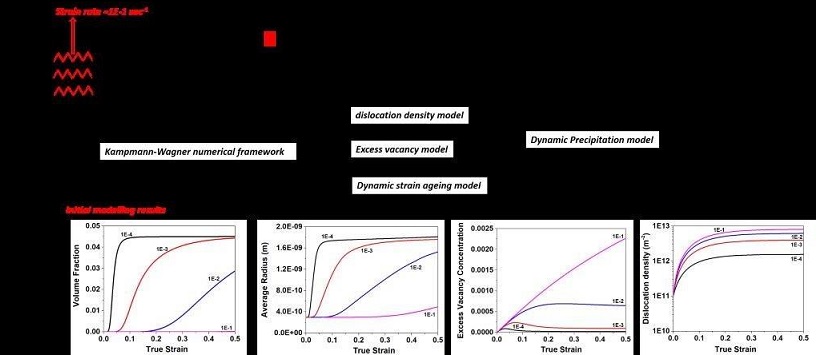

The application of forming at elevated temperatures requires knowledge of the complex interactions between temperature, time, strain rate, extent of deformation and precipitation kinetics. This demands extensive experimental trials as well as a process model where the different modules concerned with plasticity and precipitation are linked. In this project, we aim to perform monotonic tensile tests at three different temperatures and two strain rates using Electrothermal Mechanical Testing System (ETMT) followed by in-depth microstructural characterization involving XRD, SAXS, EBSD and TEM to determine the dislocation density, dislocation substructure, precipitate number density and average size and volume fraction of the precipitates. Apart from experiments, we also aim to simulate the experimental behaviour by extending the Kampmann-Wagner numerical (KWN) framework to incorporate the effect of plastic deformation on nucleation and growth rate of precipitates. The effect of plastic deformation is taken into account by specifying the contribution of deformation induced excess vacancies and forest dislocations in the model.

To date, a modified version of KWN model has been developed and trial simulations have been carried out at different strain rates ranging from 10-4 sec-1 to 1 sec-1. It was observed that strain rate has a positive impact on excess vacancy concentration which enhances the diffusivity and consequently the precipitate number density, radius and volume fraction compared with the deformation free case. Comparison of the effect of strain rate for a fixed strain reveals the competition between deformation and time (which is lower for higher strain rates). Although higher strain rates accelerate kinetics, this is predicted to be not sufficient to compensate for the reduced time (to reach a fixed strain level). Furthermore, simulations were performed for various pre-aged conditions ranging from the fully supersaturated solute condition to the peak-aged condition. In the fully supersaturated state, deformation mostly affects nucleation, whereas in the peak-aged state it affects coarsening.