Research

Data and Modelling

The 7xxx series of aluminium alloys have exceptionally high strength and are used for structural applications, however some of...

7xxx aluminium alloys are the most widely used materials in the aircraft structural application due to their high strength,...

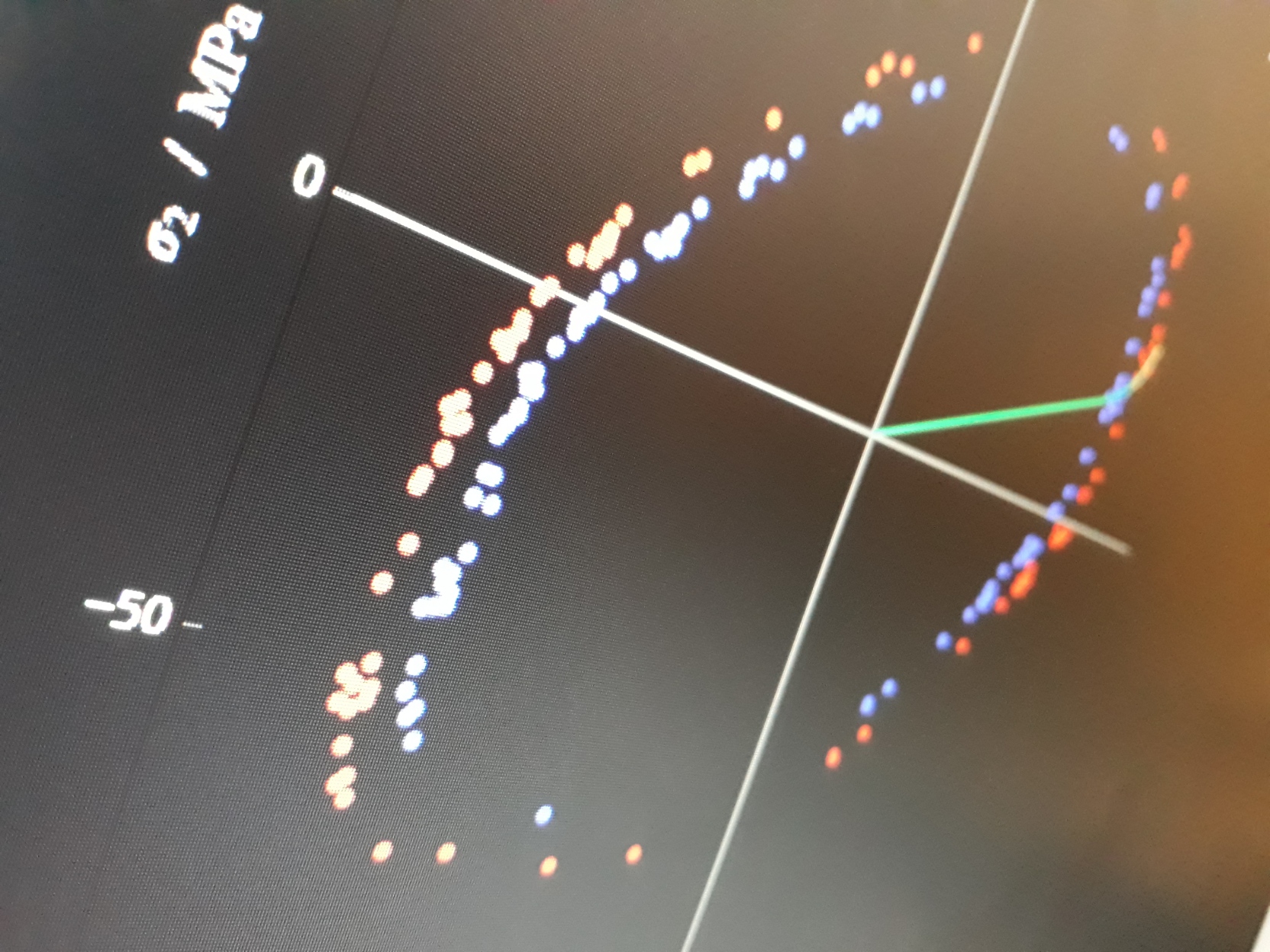

A predictive knowledge of yielding behaviour is critical to improve our understanding of the mechanical anisotropy of light alloys...

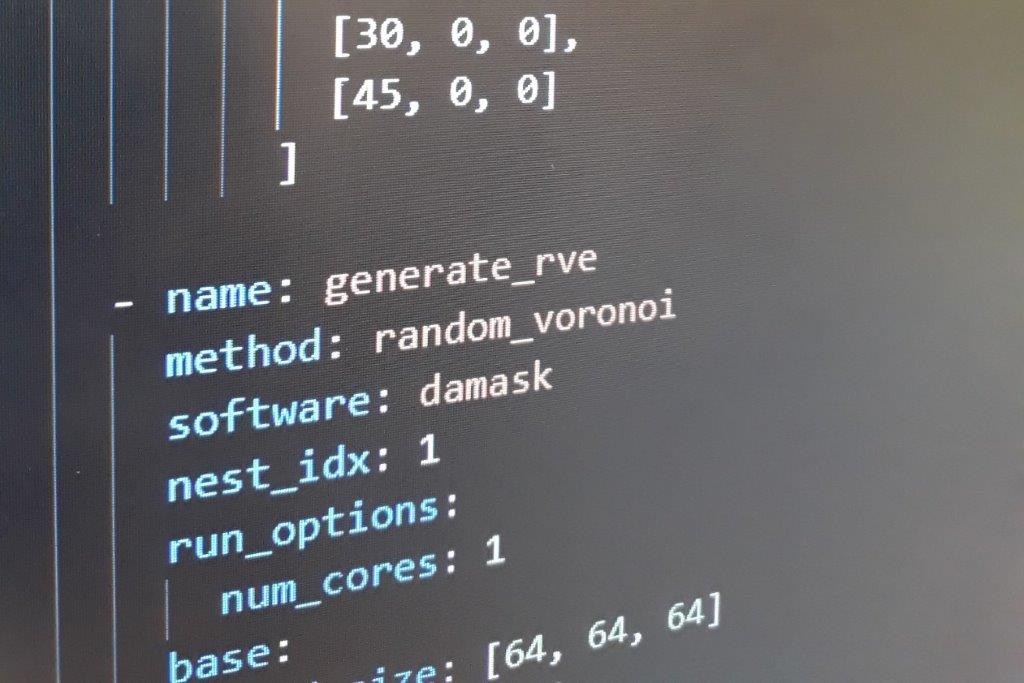

As part of the LightForm Programme, our project is focused on numerical modelling of forming processes and constitutive material...

Background: Creep-age forming (CAF) is a forming technique used for fabricating large/extra-large lightweight aircraft panel components....

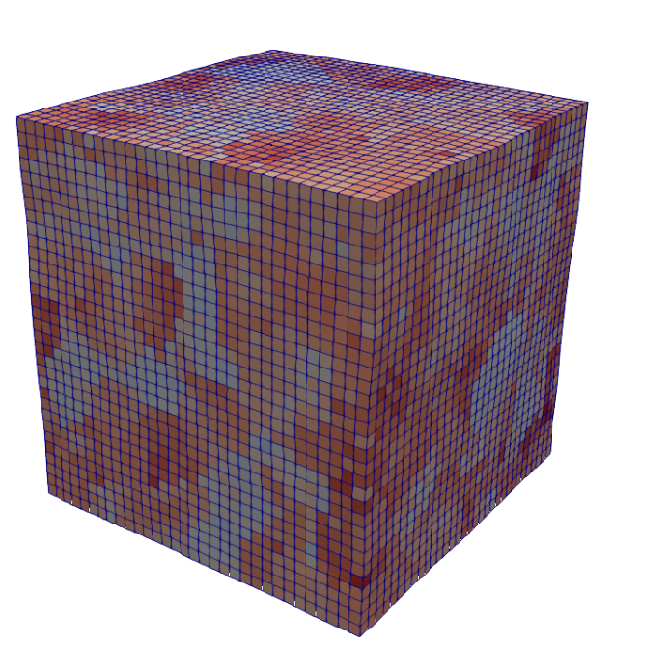

This project involves using crystal plasticity modelling to explore the effect of primary particle size distribution, volume fraction and...

Understanding formability is of vital importance to light alloy component manufacturers. In particular, the mechanical anisotropy of light alloy...

Datalight is tool developed in python which will help the data saving for LightForm project on data repository for...

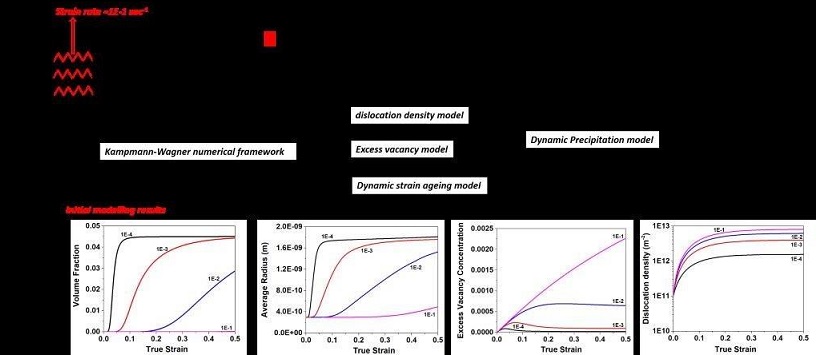

The advancement of nuclear fusion is significantly limited by the available materials that can withstand the extreme environment produced...

The Forming limit diagram (FLD), which represents the limit strains for a material deformed under the different strain states...

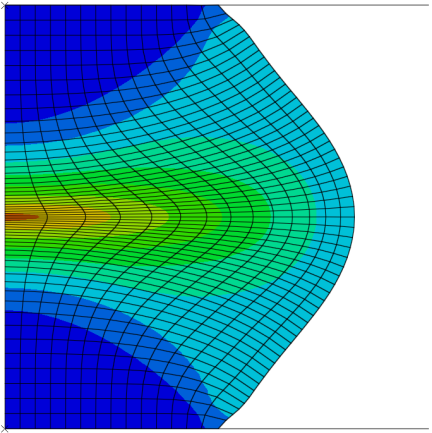

A finite element model accounting for friction, barrelling, and temperature gradient has been developed. This will be used to...

The aim of this project is to refine existing crack growth models to be more realistic of...

In this project the effects of intermetallic compound particles on the formability and mechanical properties of the...

The recent in-service durability of single crystal turbine blades has been far from ideal. Whilst we have the ongoing ...

The warm deformation performs below the recrystallization temperature which leads less additional softening due to recrystallization. The texture changes...

Despite having the key advantage of high strength to weight ratio, Al alloys lag behind in their application compared...