Research Projects

Aluminium / Data and Modelling

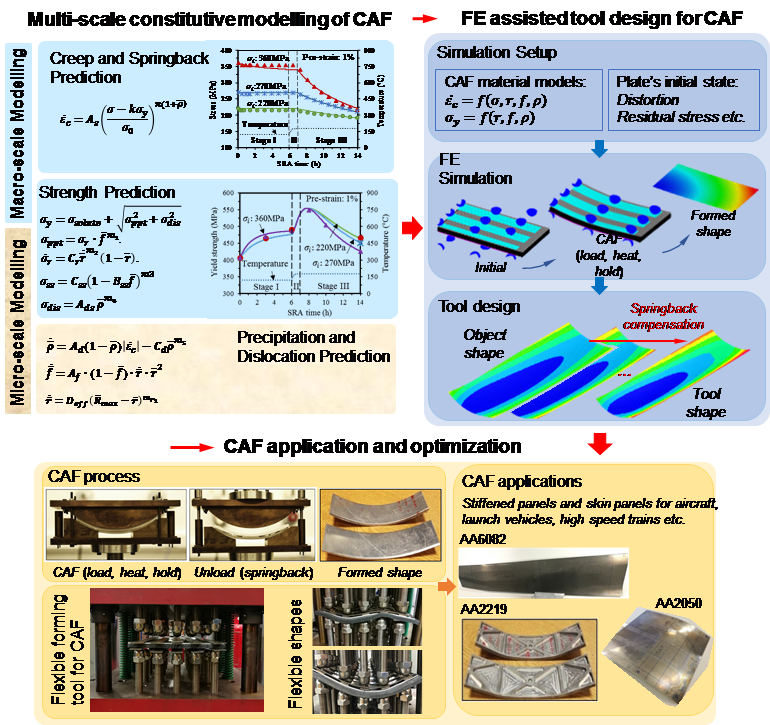

Creep Age Forming (CAF): Experimentation and Materials Modelling

Background:

Creep-age forming (CAF) is a forming technique used for fabricating large/extra-large lightweight aircraft panel components. An aluminium alloy plate is deformed inelastically through exploiting the creep/stress relaxation mechanism at ageing temperatures, thus efficiently producing a part with target dimensions, by creep deformation, as well as required mechanical properties, by age hardening. Over the decades, extensive work has been done by our group to accurately model the spring-back and final strength of the CAF components. We have successfully established the first set of multi-scale creep-ageing constitutive equations that can effectively predict both the microstructure evolutions (e.g. evolutions of precipitates and dislocations) and the macro-properties (i.e. creep/stress-relaxation and yield strength). This modelling work provides a powerful prediction tool to optimize the CAF processing parameters and tool design for the industrial applications, enabling optimum shapes and strengths in products to be achieved with shorter lead times, thus significantly reducing the costs. The developed unified creep ageing constitutive equations have been used by ESI Group (A world-leading software developer headquartered in Paris) for their commercial FE code, Pam-Stamp, for industrial applications of CAF process.

Research Gaps:

The current modelling method focuses on establishing and calibrating a set of constitutive equations using the uniaxial creep-ageing data, then applying the equations to the CAF process where stress relaxation ageing occurs. However, the creep behaviour is not necessarily comparable to the stress relaxation behaviour under the ageing conditions. Therefore, it is necessary to experimentally study the relationship between creep-ageing and stress relaxation ageing behaviours, and more importantly, establishing a model that is capable of accurately predicting both behaviours.

Aims: The current projects focus on a comparative study of the creep and stress relaxation ageing behaviour, additionally, examining the pre-stretch effects on the stress relaxation ageing behaviours.

Objectives:

- Creep and stress relaxation tests will be performed under identical ageing conditions

- Various levels of pre-stretch values will be applied to the samples before the creep & stress relaxation ageing tests

- Microstructure examination (e.g. SEM, EBSD, etc.) will be performed to enable insight into the CAF mechanism

- A set of constitutive equations will be established for predicting both creep and stress relaxation ageing behaviours