Research Projects

Aluminium

Experimental and Numerical Study of Dynamic Precipitation in Aluminium Alloys During Warm Forming Process

Context:

The need for high-strength aluminium alloys has been growing very rapidly for a decade due to their high potential for being light-weight and recyclable. However, these alloys exhibit poor formability and their manufacture has become an important industrial challenge. To improve formability, the alloy is typically worked at a higher temperature and weaker pre-temper. Many dynamic mechanisms are involved and coupled during such a warm forming operation, making the process analysis and optimization difficult.

Aims:

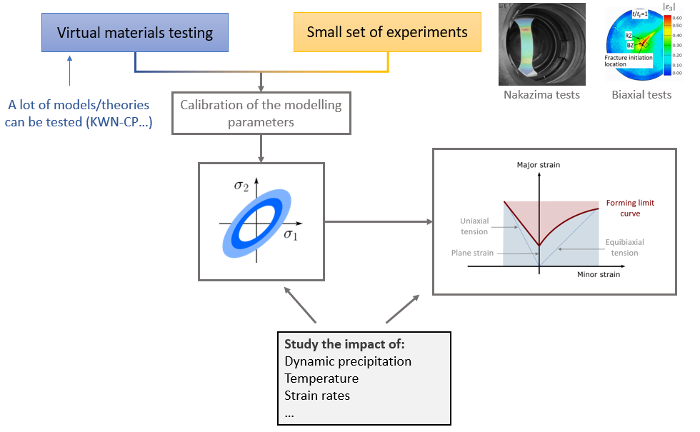

The aim of this project is to identify optimised process windows and pre-tempers for the warm forming of high-strength aluminium alloys. A modelling workflow to predict the warm formability of light aluminium alloys will be developed. Based on the Surfalex project this work will study, amongst other phenomena, the influence of dynamic precipitation, temperature and strain rates on the material formability.

Methodology:

Using virtual material testing, developed in the Surfalex project, it is possible to study the influence of material properties at low cost. This work will go further in the understanding of the activated mechanisms during the forming process. First, formability experiments (e.g. Nakazima tests and biaxial tests), microstructure data and virtual testing (based on crystal plasticity and precipitation theory) are going to be used to obtain the hardening behaviour, the yield surfaces and the forming limit diagrams (FLD) of the application material (AA7075). The results obtained will then be validated with experimental data of the formability experiments. The impact of phenomena, such as dynamic precipitation or recovery, on the formability of the material will be studied through this approach.