News, Views & Events

News

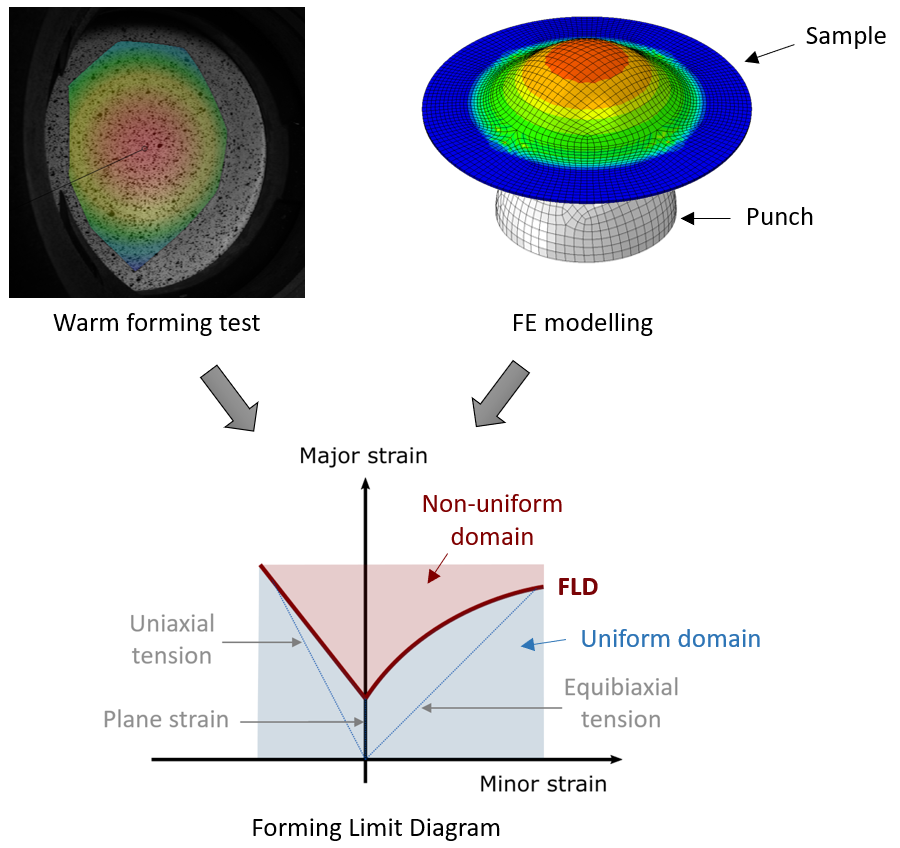

Warm Formability Study of a 7xxx Al Alloy: Experimentation and Modelling

High-strength aluminium alloys are increasingly sought after in manufacturing due to their high potential for light-weighting and recyclability. Unlike steels, however, light aluminium alloys exhibit poor formability, and their manufacture has become an important industrial challenge. LightForm researchers are currently working on the warm formability of aluminium alloys in order to increase the understanding of the different mechanisms involved during forming.

Numerous parameters can have an impact on the formability of a material including forming temperature, strain rate, pre-temper and more. Depending on these parameters different mechanisms, such as dynamic precipitation, can be activated in the material during forming. Gaining a better understanding of these mechanisms is therefore paramount to optimize the process parameters and improve the formability of the aluminium alloys.

Experimental warm formability tests are conducted at the University of Manchester by Dr Thomas Jailin and PhD student Elliot Cooksey-Nash. They are currently investigating different temperatures, strain rates and pre-tempers to obtain the impact of these parameters on the Forming Limit Diagram (FLD) of the material. In a parallel study, Dr Patryk Jedrasiak from the University of Cambridge, is developing a finite element model of the formability experiments to better understand the impact of friction during the process, and the influence of the stress triaxiality on the material formability. A robust identification of the anisotropic behaviour of the material is also being investigated by using both crystal plasticity simulations (cf. similar work on the Surfalex project) and the full-field data obtained during the forming experiments by digital image correlation. The implementation of a dynamic precipitation model, developed by Dr Madeleine Bignon, will also help understand the impact of dynamic precipitation during forming.

Preliminary results have already been obtained from the experimental and numerical studies; these results include the effects of the forming temperature and material pre-temper on the material formability. These results will be drafted soon into a journal article, as well as being presented at the ICAA18 conference in September 2022.